Industry Leading Design & Manufacture

You submit – We achieve, always

Over 65,000 designs since 1987

Products Manufactured

Your Submission

Upon quote approval, if necessary, we research the initial brief to ensure the very best result is achieved.

Advice & Ideas

We pride ourselves in our submission of creative & innovative interpretations to turn your concept into a reality!

Final Creation

Using the latest design technology, our experienced creative team submits your design – Great British Design.

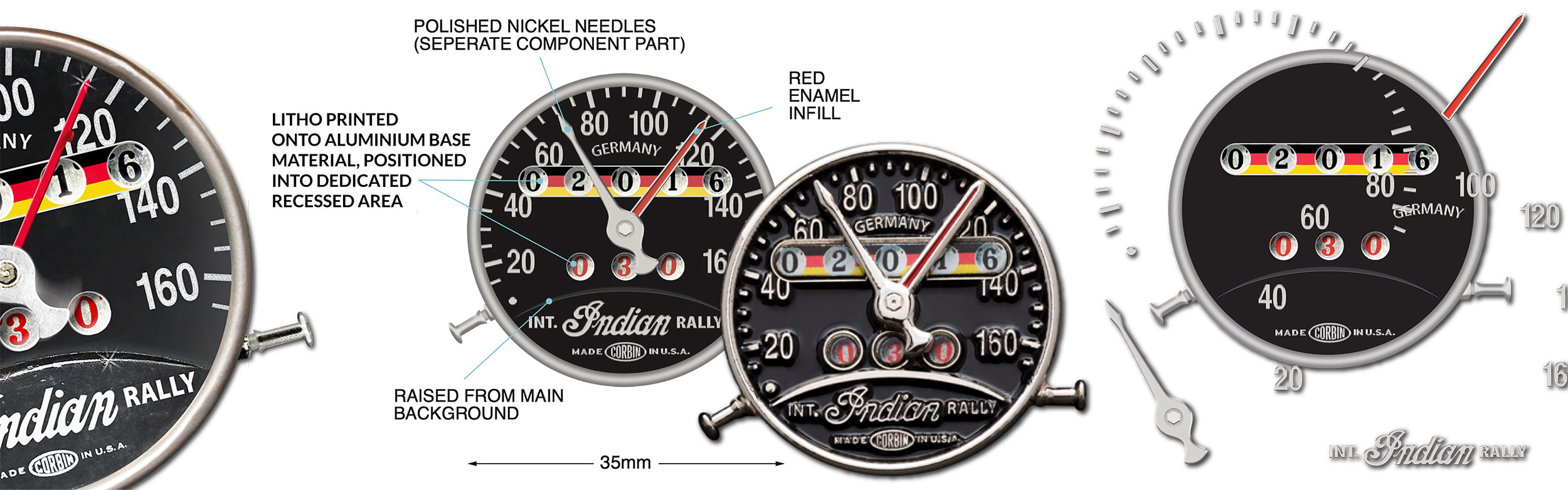

I’ve been in charge of our club’s annual and special badges for 17 consecutive years, and I was happy working with our former supplier, but as far as I can tell, ML Badges is the benchmark in this business!

Matthias – Chairman

Indian Motorcycle Club, Germany.

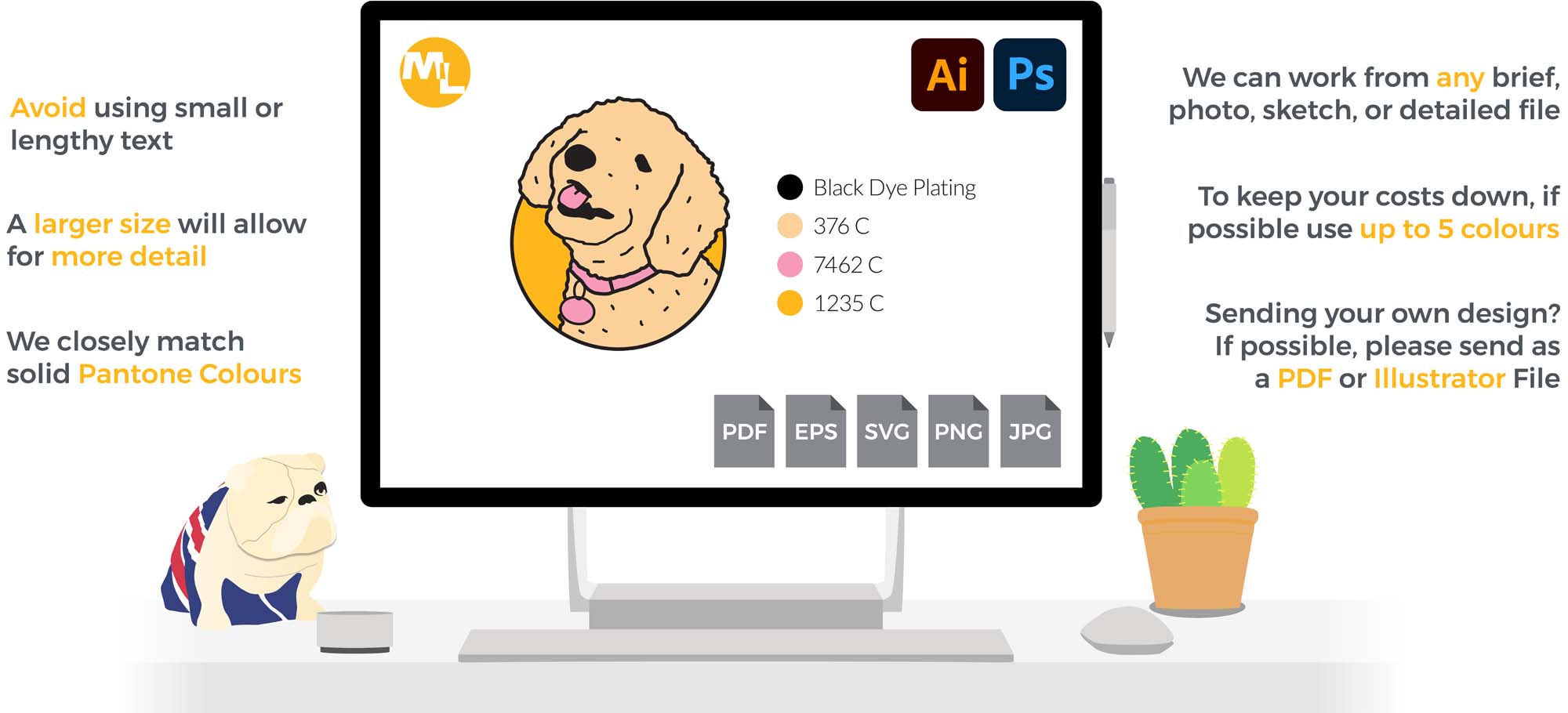

Helpful Design Guidelines

The information above applies to our most popular range of enamel products; other products such as PVC, printed, or cloth may have alternative requirements – Our team will always advise.

Our design team will always supply clients with a detailed compatible visual with various sizes, colours and plating options if required.

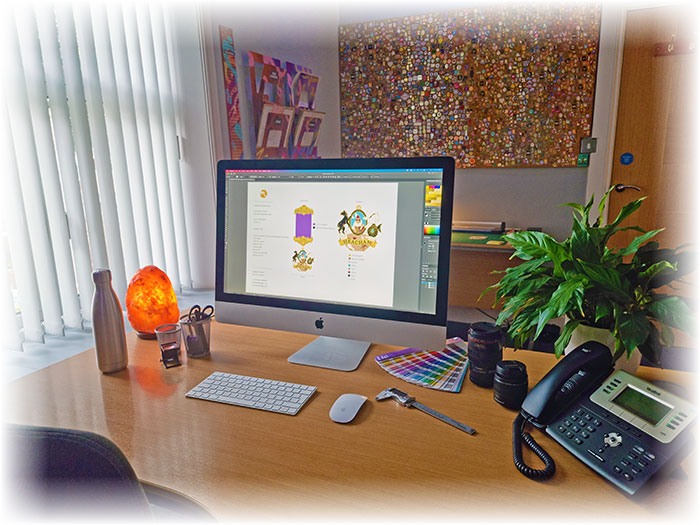

How do you design your products?

We primarily use the latest version of Illustrator from Adobe CC – All of our designs are hand-drawn as a highly detailed Vector; this allows us to work to an extremely high level of detail and produce accurate technical drawings to produce your product.

Our experienced design team can also develop and supply photo editing, quality print, website design and illustration (Caricatures, cartoons, etc.)

What is a Pantone Colour?

We use the Pantone Matching System (PMS), which is shown on your compatible visual – This solid colour is then matched close as possible within our industry.

We match any colours/specifications we are sent, e.g. HEX, RGB, CMYK, to the closest Pantone number.

What is a Die Line?

A die line is an essential border that separates an enamel colour from another and creates the overall design detail.

The electroplating (Show in Gold) is submitted at the visual stage of production.

Designer? Please note metal die lines must be at least 0.2mm thick at actual size, allowing 0.3mm for the enamel areas.